Diagnosing the reason for the motor breakdown is an essential part of the process. We have multiple tests and professional equipment in order to jumpstart the repair process.

Surge testing of A/C electric motors and generator windings displays a accurate picture of the winding and insulation conditions. Tests made can determine good, marginal or defective windings and the winding insulation before a major failure occurs. In many cases actions can be taken to head off these failures, preventing costly delays and repairs. This digital surge tester applies a predetermined voltage and captures a sinusoidal wave form for each phase of the unit under going the test. It also displays megohms and Hi-Pot measurements. All the information is used to make the correct decision on what repairs are needed.

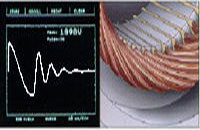

The wave form is showing a good winding. You will notice how each of the three phases overlap each other. Representing what appears to be only one wave line. Pictured is the windings that are being tested, no faults are present.

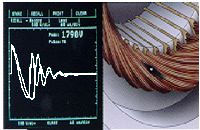

If there is a Turn to Turn / Phase to Phase weakness The wave patterns will separate and appear unstable This is an indication of imminent failure. The motor should be serviced immediately. Pictured is a turn to Turn / phase to phase fault.

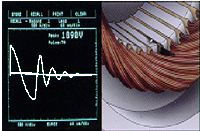

If there is weak insulation the wave pattern will indicate the weakness. If a motor with a turn to turn fault short stays in service circulating currents may produce hot spots and the ground wall insulation will eventually burn up causing a shut down. Pictured is a ground fault.

Our multi-step rewinding process is designed to limit vibration and minimize dirt and debris in the motor. We use a state-of-the-art baking and cleaning process in order to restore motors to factory specifications.

Stripping ovens are an integral part in the repair process. Water injection temperature controlled burning of electric motor & generator stators alleviate the damage caused if the oven has a thermal runaway, simply put the water injection system keeps the temperature at the preset levels overcoming the potential of lamination core iron damage due to extreme temperatures, in some cases up to 1500 deg. F in the stator core can be reached.